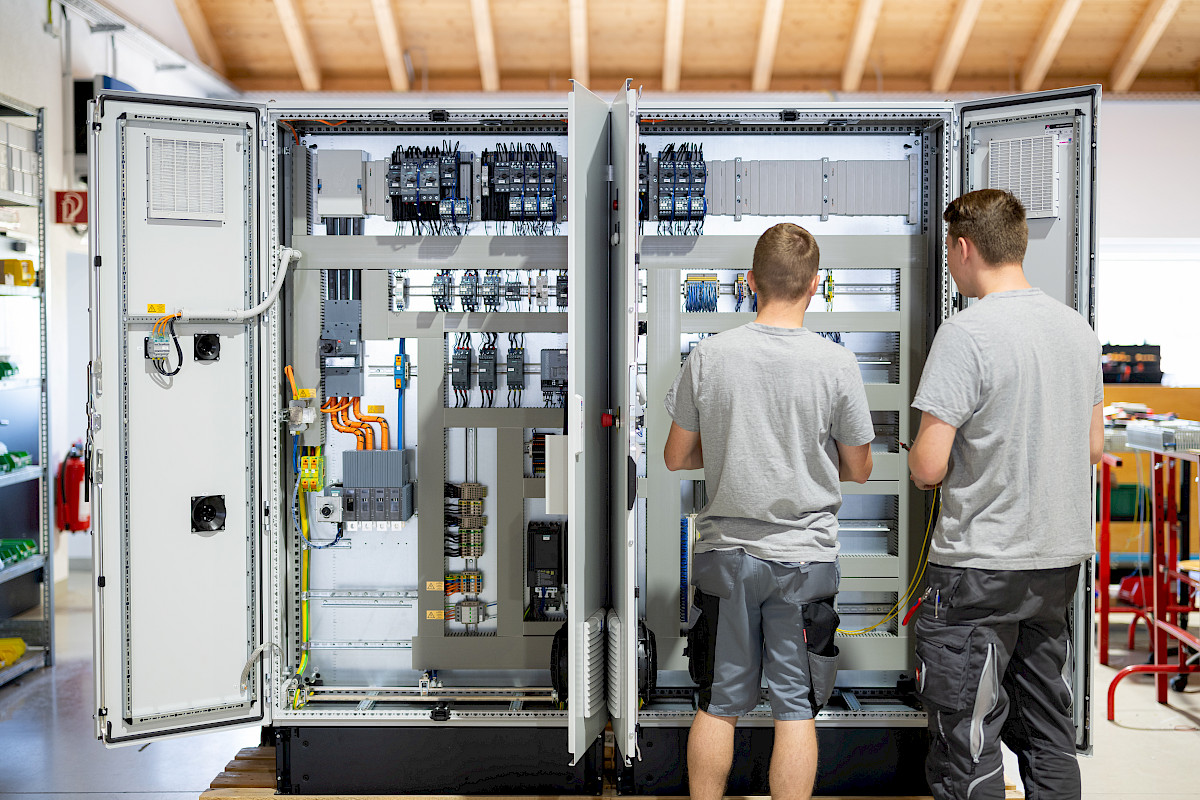

Manufacturing of Control Cabinets

according to Your Individual Requirements.

As specialists in control and low-voltage switchgear, up to the manufacturing of distribution systems, our product range knows no limits. Whether it's single or series cabinets, control panels, command or terminal boxes – we assemble, wire, and test cabinets of all kinds in compliance with current standards and regulations.

We distinguish ourselves particularly through high flexibility, adherence to deadlines, and short delivery times. These high standards and quality demands are upheld through continuous internal and external training, as well as an open communication culture.

Precise Control Cabinet Assembly

and Wiring:

Meet Your Requirements with Expertise and Compliance with Standards.

- Whether it's single or series cabinets, control panels, command or terminal boxes – we assemble, wire, and test cabinets of all kinds in compliance with current standards and regulations.

- We manufacture tailored solutions as well as small and large series for you. Optionally, we also serve as an extended workbench.

- Our range of services extends from the manufacturing, installation, and maintenance of switchgear and control systems for various applications in control, automation, and plant engineering to special machine construction.

Housing, mounting plates, or other metal parts are processed on our Steinhauer CNC center. Rails, channels, and other accessories are processed using appropriate tools. Dimensions and shapes are derived from pre-created CAD models.

With a Metzner Triathlon 2000 for automatic wire harnessing, we obtain individual wires with appropriate length and destination labeling at the ends via inkjet printing, as well as various options for wire end treatment.

With modern printers from Weidmüller and Phoenix Contact, we are able to provide a variety of different labeling materials for the identification of components, cables, and control cabinets for you. Plastic, aluminum, and stainless steel can all be printed. Mounting is done based on predefined layouts and in constant alignment with the item bills of materials from the circuit documentation.

Pre-fabricated wires simplify and accelerate wiring. Checking the wires for conformity with the circuit diagram significantly reduces wiring errors. Project lead times can thus be significantly shortened. Furthermore, the replacement of components becomes child's play due to the clear identification of all components.

Specially trained employees conduct both electrical safety tests according to various standards and comprehensive functional tests. They are supported by state-of-the-art measuring devices and various manufacturer-specific programs for wire testing. Our customers are welcome to verify the quality of the products on-site as part of a customer acceptance test.

Automation

Read here to learn about the services we offer in the field of automation.

Hardware Engineering

Read here to learn about the services we offer in the field of Hardware Engineering.

Plant Inspection

To ensure safe production, we inspect, measure, test, and assess your electrical systems and machinery.